Printed electronics for health

Printed electronics is a source of innovation in healthcare. It meets the challenges of the functions expected of medical devices: thinness, lightness, strength, flexibility, conformability, etc. It is a new generation of electronic devices adapted to the comfort and daily use of patients. The Institute develops, structures and leads the Printed Electronics – Health ecosystem by creating synergies between the expectations of hospital practitioners in terms of medical devices, the technological and scientific expertise of partner laboratories and the know-how of electronics and IOT manufacturers.

Printed electronics

This technology is not a substitute for “traditional” (i.e. silicon-based) electronics but a complement for a number of applications. Printed electronics is a multidisciplinary field that calls upon different skills in chemistry, physics and electronics. This combination of new materials and large-area production techniques opens up a wide range of electronic functions that can be manufactured and integrated at low cost.

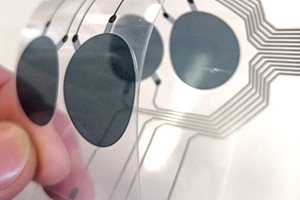

Simple or complex electronic functions are realized with organic or inorganic materials printed on flexible or rigid substrates. The specifications of each product define the printing processes, the functional ink formulations and the associated substrates.

In the healthcare sector, the prospects for electronic functions available on flexible, light and thin substrates are multiple and foresee an exponential growth.

Medical devices

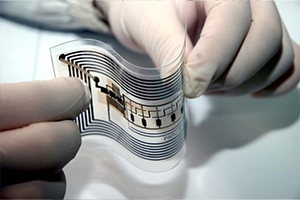

A number of products connected to printed electronics are currently being developed to produce thin, flexible, light devices that can be easily integrated into existing tools and that can be recycled. Various properties are brought to them: extreme sensitivity to deformations, vibrations, energy or temperature variations. These devices require only low energy consumption compatible with nomadic applications. Moreover, these devices can generate their own energy from vibrations or ambient heat.

THE ADVANTAGES OF PRINTED ELECTRONIC

Organic electronics is a large area, flexible, low cost and high function electronics. Organic or printed electronics has many advantages:

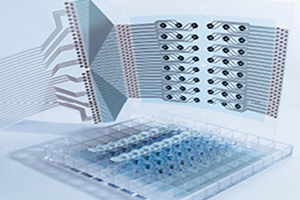

Size of the circuits: it is possible to realize electronic functions distributed on large surfaces: homogeneous luminous surfaces of several dm², sensor arrays on surfaces from dm² to m².

Nature of usable substrates: the conformability and flexibility of substrates allow us to imagine new applications and new ways of integrating electronic functions into final products with current printing processes.

Lightness and robustness: these major advantages are a consequence of the plastic substrates used. The mechanical robustness of plastic circuits is a major asset, especially for mobile applications.

Ease of fabrication and self-assembly: organic semiconductors are easier and more economical to fabricate, both in the laboratory and in the industrial phase. Chemical engineering is developing self-assembling molecules and printing techniques are already producing high yields.

These manufacturing methods are in contrast to the expensive and complex processes of inorganic technologies that require huge infrastructures (clean rooms) and very high heating temperatures.

Investments and costs are much lower than in silicon: while the investment for a silicon factory on 300mm wafers (45nm or 32nm technologies) still amounts to more than 3 billion dollars, the cost of an organic electronics factory can be estimated between 100 and 200 million dollars. Thus, if the performance of a silicon chip and an organic circuit are difficult to compare, the cost/performance ratio makes the organic option relevant for large circuits.

This technology is therefore particularly accessible to SMEs. Finally, thanks to printing tools, cycle times between design and manufacturing are very short (around one month), which meets the growing need for customization of products and applications.

An environmental technology

Printed electronics leave a small carbon footprint in the development of medical devices. The manufacturing process is based on solutions used at ambient conditions. The production processes are based on additive deposition of very thin layers with a reduced number of steps. By contract to conventional cleanroom technologies, printed electronics uses low power and water consumption. In addition, printed electronics uses non-toxic substrates such as plastic (potentially recycled), paper, glass substrates or other eco-friendly materials.

The overall approach of the printed electronics players to eco-design is the introduction of the circular economy from the product design stage.

In production, organic electronics saves the extraction of rare metals (platinum, etc.) and large quantities of water used in conventional microelectronics. Thanks to their low cost and ease of fabrication, the industry sees in organic semiconductors the possibility of producing disposable electronic devices such as RFID antennas, flexible batteries or sensors. The reduction of material, energy and water consumption also requires a reduction of rejects and therefore a better control of the manufacturing process.

Printed electronics, a sector of the future

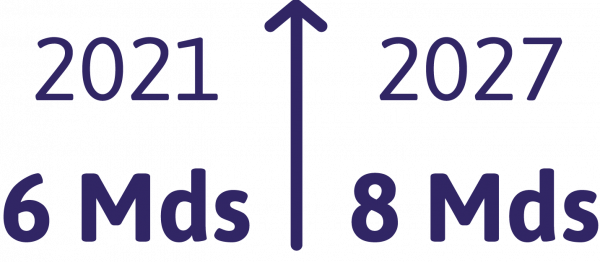

The healthcare market is currently waiting for high-performance diagnostic tools. Printed electronics, a technology with low energy and material consumption that can be easily integrated into connected objects, meets these expectations perfectly.

The markets in perspective

Point Of Care self-tests

CAGR 4%/year *

Skin patches

CAGR 15%/year *

Connected biosensors

CAGR 32%/year *

RFID, NFC

* Grand View Research ** Fortune Business Insignt